DIGESTER PROCESS

Food waste digesters safely break down all organic food waste, cooked or uncooked from plate scrapings, left-over takeaway food, meat, fish, small bones, bread, dairy products, vegetable peelings and fruit, turning it into a liquid format.

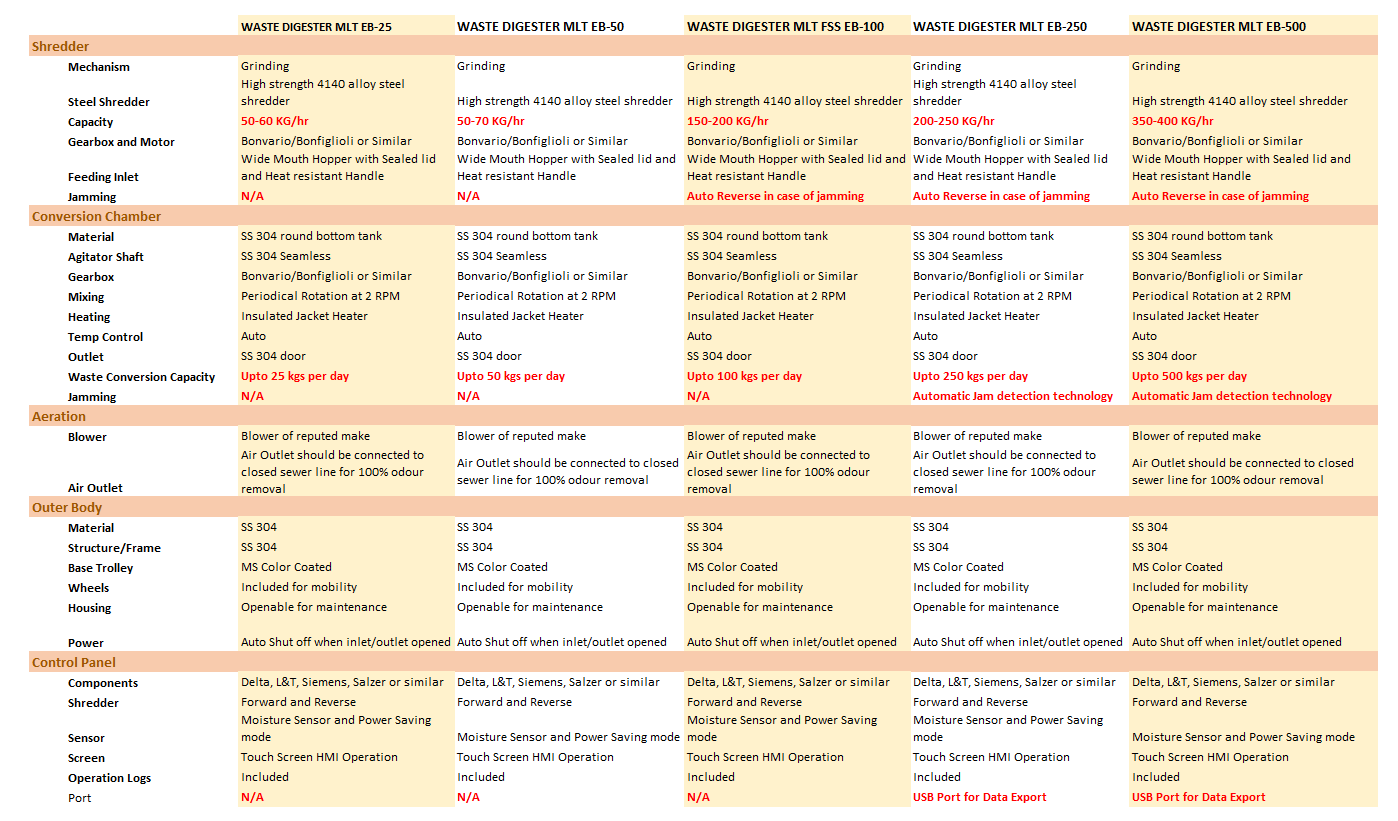

Experience top-notch performance with our cutting-edge waste management system. Our shredder features inbuilt cutters with twin shafts and a robust grinding mechanism. Crafted from high-strength 4140 alloy steel, the shredder blades are hardened and ground to perfection. The equipment is designed for efficiency, with a wide mouth hopper, sealed lid, and heat-resistant handle for easy and safe feeding. The conversion chamber boasts a tank made of SS 304 round bottom material and an agitator shaft of SS 304 Seamless, ensuring durability and efficient mixing. It incorporates features like a periodic rotation at 2 RPM, an insulated jacket heater with auto temperature control, and a dual inlet for versatile operation. The blower, utilized for aeration, is sourced from reputed manufacturers. The outer body is constructed from SS 304 material, while the base trolley is MS Color Coated, making it highly mobile and easily maintainable with a completely openable housing. Our control panel is equipped with switches, displays, and electricals from renowned brands like Delta, L&T, Siemens, Salzer, and more. It offers advanced features, including a temperature controller, forward and reverse options for the shredder, a moisture sensor, power-saving mode, touch screen HMI operation, and operational logs for future reference. Discover the future of waste management with our comprehensive solution.